Most of the time I seem to be organizing or improving my shop in some way. So much so that I think I probably spend a good amount of available shop time doing that. Now I have found that when I am working on an actually project that isn't related to that I find I am more efficient because of a neat and organized shop. As some of you might now I have started making videos when I can of projects I am making. At first it was just to share with the rest of the woodworking community what I had going on in my shop. It has since since morphed into not just showing what I was doing but how I was doing it and turned into

Woodshop Confessions. I love the fact that there is an increasing amount of free woodworking content out there for everyone. If fact if you ask my wife, I'm either cleaning or organizing my shop, watching woodworking videos on YouTube, or a combination of them both.

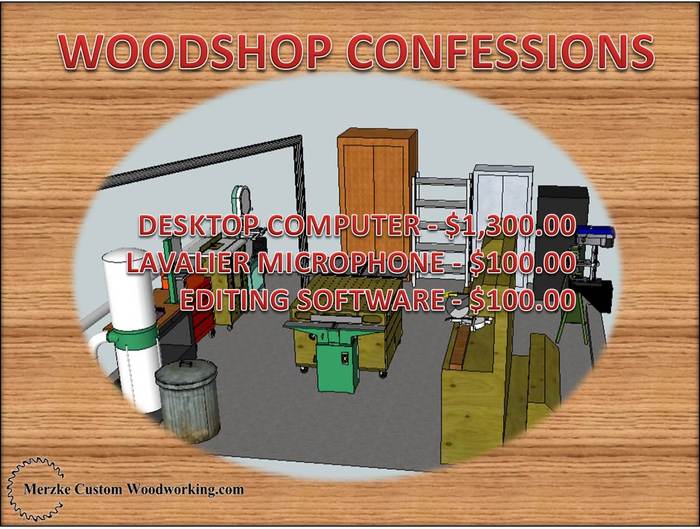

In order to try and improve the quality of Woodshop Confessions I decided that I should do some upgrades. I found three areas that I believe that I can make some improvements on the production side of my YouTube Channel and those are video, audio, and editing. Well four if you count me getting more comfortable with being in front of a camera.

The first of these categories was video. I started off using my Iphone to record the video and although the quality was not bad at all, I quickly discovered that available memory was an issue. This couple be partly because I had the 16GB Iphone and with all the cool apps that I have I didn't leave much memory. I would have to do a little recording and then go inside to dump the video on the computer and then run back into the shop for some more. To fix this I purchased the GoPro Hero3 since it was on sale because of the release of the Hero4. This really help make things a lot easier since with the current SD card I have in there I can film in HD for over two hours.

The next two improvements I'm asking for your help in making. I have started a

Kickstarter Campaign to raise some money to upgrade my audio and editing equipment. I would really appreciate your support either by way of pledging your support or just by sharing this post or the link to my Kickstarter page (

https://www.kickstarter.com/projects/706728814/new-editing-and-audio-equipment-for-woodshop-confe). I have added a few rewards for pledges of donations. If we successfully reach our goal of $1500 by the allotted time I will use those funds to purchase the equipment needed to increase the audio and editing capabilities. I'm sure this won't fix my looks or the stumbling and mumbling I do on camera... but we can hope!

Thank you very much for taking the time to join me. If you have not seen Woodshop Confessions before than I encourage you to swing by and check out some of the videos I have posted. There are links to all my social media sites on

www.merzkecustomwoodworking.com.